Products & Services

01. Tooling Manufacturing

We specialize in manufacturing cold forming tools with high dimensional accuracy or complex geometric structures, such as multi-piece nib, spline gear dies, and open-die. We are committed to providing rapid response and helping our customers analyze issues encountered during the cold forming process. By offering practical cold forming solutions, we work together with our clients to resolve challenges and maximize the advantages of cold forming technology.

For cold forming accessories (such as pin, cutting knife, and finger, etc.), we ensure premium quality while maintaining some of the shortest lead times in the industry, minimizing downtime as much as possible.

Common Tooling & Accessories Structure:

1. Intense beam tooling

2. Multi-piece nib

3. Conti Fasteners AG’s series

4. Spline gear tooling

5. Complex cavity & header contour

6. Open-die

7. Accessories

02. Improving & Designing

Improving:

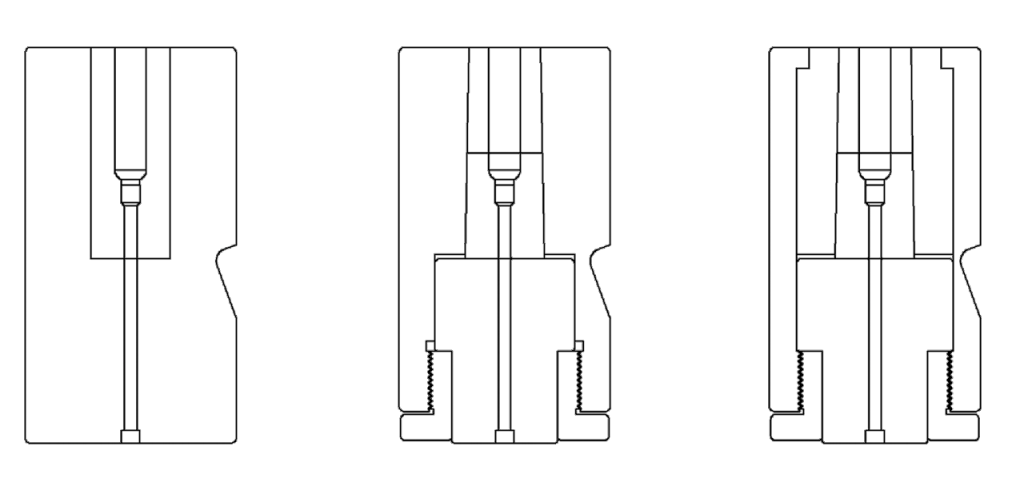

For tools of the same shape, there are often multiple design approaches for their internal structure. Broadly speaking, these can be categorized into monolithic and assembled designs, each with its own advantages and disadvantages.

When providing technical consultation to customers, we take the time to thoroughly understand their specific needs. By analyzing factors such as the performance of existing tools and the forming process, we evaluate aspects like tooling cost, interchangeability, stability, the number of cycles components can endure, and overall lifespan. Based on this analysis, we offer tailored improvement solutions.

For tools still in the development phase, our primary focus is on ensuring stability, prioritizing the ability to achieve correct product formation. For customers whose tools are already running smoothly, we shift our focus to cost optimization, exploring ways to enhance efficiency and reduce expenses while maintaining performance.

Different internal structure example:

Designing:

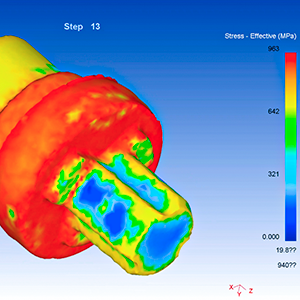

For customers who require tools development, we analyze the feasibility based on the specifications of their cold forming equipment. Utilizing finite element analysis and our extensive experience in the material forming process, we provide a range of tooling design solutions. At the same time, we continuously monitor the actual performance of the tools during use and make ongoing improvements until stable and reliable results are achieved.